The software tool used more and more every day by engineers and technicians that's revolutionizing design of cold rooms

Already a CoolProRoom subscriber? Enter directly here

CoolProRoom isn't just a calculator

Calculation speed and precision in a single tool

Calculation of cooling capacity

You will be able to calculate the thermal load and cooling capacity for up to 10 types of refrigerated rooms, allowing a correct selection of components and equipment. The software also automatically generates editable calculation reports ready to be included in your projects.

Calculation speed

Whether the cold room design is for fruit, meat or any other type of fresh or frozen product, designing cold rooms is now faster and more accurate than ever thanks to the Guided Wizard provided by the COOLPROROOM software. Time is money!

Available on all devices

PC, tablet and smartphone. If you are out of the office, you can make a quick calculation and make an "on-the-spot" offer to your customers.

Special cold rooms

The software allows freezing and rapid cooling tunnel design, as well as temperature and humidity controlled dryers and warehouses.

Calculation of freezing, cooling and drying times

The first software on the market that allows you to calculate the freezing times for food, rapid cooling for pre-cooked dishes and drying cycle duration for ham, cheese and cold meat.

Optimization and energy savings

The COOLPROROOM software allows you to optimize your design for any cold room, establishing adequate insulation panel thicknesses, as well as refrigeration equipment adapted to the customer's needs, obtaining high energy savings.

DESIGN ANY TYPE OF COLD ROOM

FREEZING ROOMS

For storing products that have previously been frozen in a blast freezer. Usually the goods enter at 14 ºF, and the temperature is then lowered to -4 or -13 ºF, to preserve the product for several months.

COLD ROOMS

For storing fresh products. The product enters at 59 to 86 ºF and its temperature is lowered to 32 or 41 ºF. The fresh product can be kept for a shorter time than the frozen product.

TUNNEL BLAST FREEZERS

These are special cold rooms for freezing products that are entered unfrozen. Freezing must be fast to maintain the quality of the product. The product enters the blast freezer and is frozen to about 14 ºF, and then stored in a freezing room.

TUNNEL BLAST CHILLERS

Special refrigeration cold rooms for rapidly cooling products that usually come from industrial kitchens and ovens. The product usually enters at a temperature between 140 and 194 ºF, being cooled to about 41 ºF, and then stored in a refrigerated cold room.

REFRIGERATED ROOMS

Rooms dedicated to industrial processes, food handling, or reception and dispatch of goods. These rooms are usually kept at a temperature between 50 and 59 ºF, seeking a balance between the preservation of the product handled and the comfort of the operators. The distribution of air at low velocity in the room is essential to avoid disturbing operators with irritating air currents.

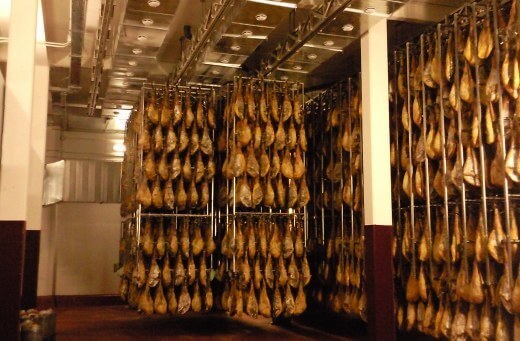

DRYING ROOMS

Special cold rooms for drying and curing food products such as hams, sausages, cheeses and salted fish. The product usually enters with a high moisture content, between 85 and 95 %, and must be dried to 35 or 60 % depending on the type of good. The main component of the thermal load in this type of room is the latent heat associated with the drying of the product.

What are you waiting for to try this incredible work tool?

Cancel your subscription at anytime

Large and constantly growing database of products

We have a flexible database that is continuously growing with information and product parameters

Parameters available in the software:

• Tª and R.H. storage

• Inlet and final product temperature

• Product water content (initial and final)

• Number of daily renewals for ventilation

• Product shape

• Protein, fat, carbohydrate, fiber and ash content

• Specific heat of fresh and frozen product

• Thermal conductivity of fresh and frozen product

• Density of fresh and frozen product

• Freezing temperature

• Freezing latent heat

• Respiration heat

• Product critical moisture

• Product-ambient equilibrium moisture

The database also includes extensive information on insulating materials for cold rooms, as well as a multitude of reference data influencing refrigerated enclosures, which the designer usually has to search for in the literature. COOLPROROOM is not only a calculation tool, but also a source of useful information.

What do refrigeration technicians think about the CoolProRoom Software?

How much is the software?

MONTHLY SUBSCRIPTION

PRO Version

* 6 room types

(cold rooms, workrooms, tunnels, drying rooms)

$59 / month

21-day free trial

Cancel your subscription at any time

ANNUAL SUBSCRIPTION

RECOMMENDED (two months free)

PRO Version

* 6 room types

(cold rooms, workrooms, tunnels, drying rooms)

$590 / year

21-day free trial

Cancel your subscription at any time

MONTHLY SUBSCRIPTION

BASIC Version

* Only 3 room types

(cold rooms and workrooms)

$14 / month

21-day free trial

(During the test you will be able to use the PRO Version)

Cancel your subscription at any time

ANNUAL SUBSCRIPTION

RECOMMENDED (two months free)

BASIC Version

* Only 3 room types

(cold rooms and workrooms)

$140 / year

21-day free trial

(During the test you will be able to use the PRO Version)

Cancel your subscription at any time

Reports and calculation lists

In addition to being an intuitive application with vast amounts of information, COOLPROROOM also allows you to obtain reports and calculation lists of cold rooms to add directly to projects and technical documentation. These reports have all the necessary information about the calculation of refrigeration needs requested by Industry Agencies for the legalization of industrial facilities. These very detailed reports can be exported to .docx format, to later be edited with programs like Microsoft Word, OpenOffice, etc.

Try the software free for 21 days with no obligation

Cancel your subscription at anytime